|

Mobile terminal (portable data terminal)

Modern technologies allow trade and warehouse inventory management to

be automated. Due to automation, personnel load can be considerably

reduced, and even one person can perform the inventory of thousands of

items and draw up all the necessary documents with relative ease.

The portable data terminal allows data about items to be acquired and

transferred to the companyТs database. The specifics of the operation of

secure storage warehousing businesses, in which the flow of items is

constant and needs real-time control, implies continuous connection with

the companyТs database and instant transfer of information about the

registered flows of items to the database.

The mobile terminal allows the following types of items to be

processed:

1. Items with individual or serial barcodes.

2. Items without barcodes identifiable by stock numbers or item names.

There is an option of entering the data concerning a new item directly

from the mobile terminal; in such case the label will be printed on the

portable printer.

3. Master-boxes with varying quantities in the box.

4. Piece items identifiable by serial numbers in the barcode.

5. Items with weight barcodes.

6. Unidentified items which are marked with bin locations until they

have been identified and sorted.

Incoming items are generally processes as marked, unmarked and not

subject to marking. If the incoming marking is not sufficiently

informative, it can be replaced or supplemented with the warehouseТs

marking.

He mobile terminal has the following functions:

TRANSFER OF TASKS B/N OFFICE AND WAREHOUSE, WORK MONITORING Ц

separate task lists for pre-scheduled receipt, detailed receipt,

pre-scheduled pick-up, issue and loading to the vehicle. In the form of

prominent colour-coded indication blinking in red and the number of the

documents forwarded to the warehouse on each list.

UNLOADING Ц the transfer of the items that have arrived from

the medium of transportation to the sorting area.

DETAILED RECEIPT Ц the sorting of the items that have arrived

and their placement in storage bins.

PRELIM. PICK-UP Ц the pre-scheduled pick-up for issuing or

consolidation of the items ordered on pallets without writing them off

the warehouse inventory for placement in the pick-up and issue area.

PICK-UP FOR ISSUE Ц direct issue from the warehouse upon the

customerТs order, with consolidation during the pick-up, on pallets or

without them.

LOAD FROM PALLETS Ц the issue of the items assembled on

pallets with an option of checking that the pick-up has been correct.

ISSUE ON PALLET CHECKING Ц the mode for checking that the

pick-up of items on pallets has been correct.

INVENTORY Ц an optional mode to be set up for each customer

separately in accordance with the peculiarities of the turnover in

addition to taking inventory of the pallet and the bin,

PALLET RELOCATION Ц the relocation of an individual pallet,

including the relocation initiated by a warehouse employee, for the

purpose of cargo placement optimization or pre-scheduled relocation for

pick-up without changing the documented status of the items.

BOX RELOCATION Ц the relocation of an item of goods, including

the relocation initiated by a warehouse employee, for the purpose of

cargo placement optimization or pre-scheduled relocation for pick-up

without changing the documented status of the items.

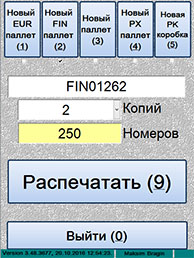

NEW PALLET Ц the creation of a new pallet number with the

option of printing the pallet sticker on the portable printer. There is

also an option of bulk printing of labels with consecutive numbers and

with the register of numbers in order to prevent the duplication of

pallet numbers.

NEW BOX Ц the creation of a new box number or piece item with

the option of printing the sticker on the portable printer. There is

also an option of bulk printing of labels with consecutive numbers and

with the register of numbers in order to prevent the duplication of box

numbers.

CREATE PALLET ITEM CARD Ц the creation of a new item card in

the course of item identification. There is an option of printing

stickers for boxes or piece items from the form of data entry of the

item card.

IDENTIFY ITEM Ц identifying the name and other item attributes

by means of the barcode.

BIN CONTENT Ц taking inventory of the items in the bin.

PALLET CONTENT Ц taking inventory of the items on the pallet.

PUT BIN ON PALLET Ц a service mode assisting in the initial

location of items in bin locations and in the replacement of pallets /

pallet stickers.

A bin location warehousing module has been integrated in the

WMS.Management software package. The user can receive information about

stock balance and the actual location where the items are stored at any

moment, including the precise specification down to the end bin. The

implementation of bin location warehousing technology is necessary so

that the storage of items can be streamlined, stock optimization methods

can be devised and interwarehouse hauling can be reduced. The bin

location warehousing technology is based on barcoding and is organized

by means of numbering the bins, pallets, items, etc.

The office-installed part of the bin location warehousing module, which

is used as the basis for operating the mobile terminal, features options

for viewing and correcting data as well as printing out documents

concerning the status of the cargo on the basis of its physical

location. The reporting system allows the status of the item to be

viewed in real time, on a particular date, and on the basis of arrival

and issue turnover broken down by the following attributes: the

warehouse (physical or customs warehouse), customer, document, order

number, stock number, name, number of the container or transportation

unit, bin number, piece barcode, pallet barcode, number of the physical

operation, etc.

The bin location warehousing module and the mobile terminals

connected to it work around the problem which arises when it is

impossible to pick up or place the cargo and to make changes to its

documentation at the same time. Now the cargo can be warehoused upon

arrival or picked up before dispatch while it is simultaneously getting

customs clearance, because information is available in two databases:

the data concerning documents and the data concerning the physical

location.

The interface of the software can be provided in any language

depending on the customerТs preferences (Estonian, Russian, English,

Latvian, etc.).

ќсновное меню мобильного терминала

|

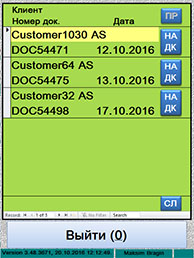

ѕул (список) задач по приему

|

ƒокумент по приему

|

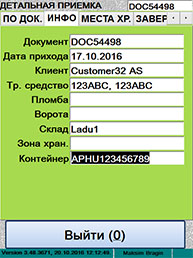

ќбща€ информаци€ о приеме

|

|

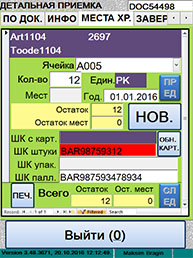

–егистраци€ товара при детальной

приемке

|

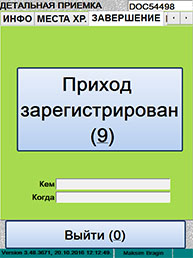

–егистраци€ окончани€ детальной

приемки

|

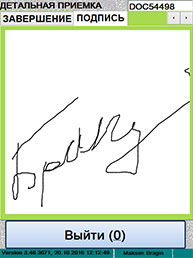

ѕодпись при

окончании детальной приемки

|

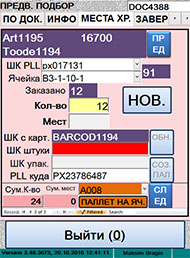

| —писок товара дл€ предварительного

подбора

|

–егистраци€ подобранного

товара при предварительном подборе

|

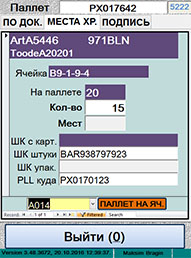

»нформаци€ о расположении товара

дл€ подбора

|

ƒетальные указани€ программного

комплекса по подбору товара

с €чеек

|

| ѕерестановка коробок

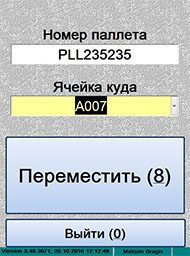

|

ѕерестановка паллета

|

ѕечать этикеток дл€ паллет

|

|